Water jet business

Water jet business

Among the most speedily developing service manufactures is that of industrial upkeep, and more particularly, water jetting or water blasting. Similar to any new or developing manufacture, particular criteria and rules are deficient, and the manufacture is imparted to control itself. Luckily for the water jetting manufacture, almost all of the companies offering this service are professionally led and fight to set every caution needed to safeguard the concerns of employees and customers.

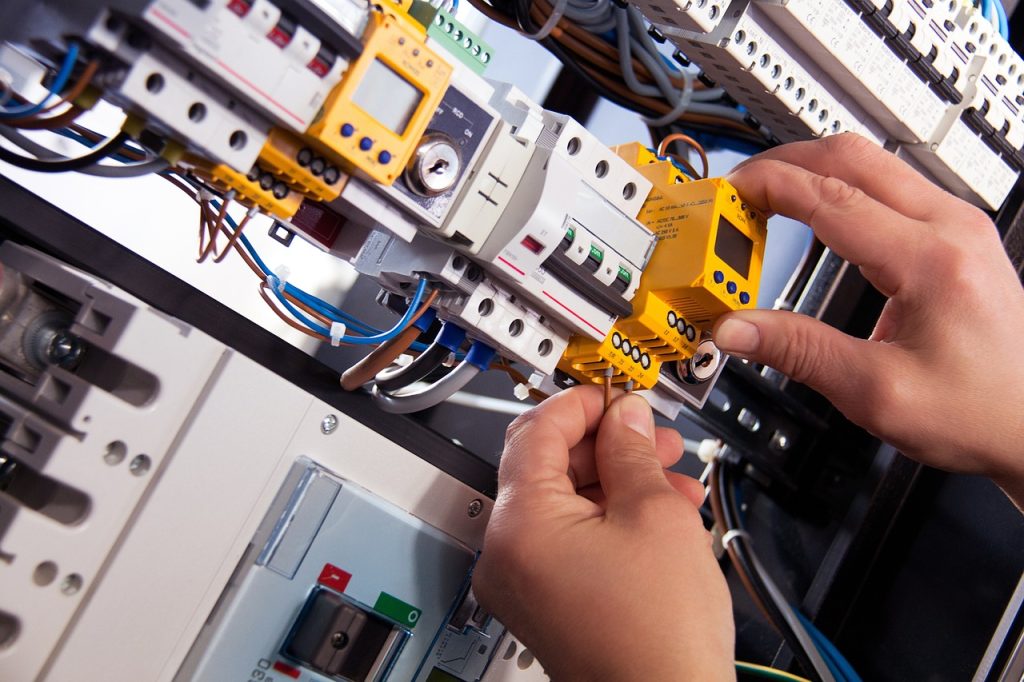

Though most people consider water blasting as the home Water jet business method of the pressure washer, where pressures can achieve as high as 1,500 psi, industrial versions work at pressures up to 40,000 psi. The pressures developing from this gear are strong sufficiently to cut through steel, so one can think of what the stream could cause to human flesh. Additional risks related to this manufacture comprise those acquainted with the building manufacture, such as confined space entry, fall risks, trip risks, eye and respiratory risks, electric shock risks, and prospective chemical vulnerability. Of specific concern to the industrial cleaning manufacture is the probability of water jetting or water blasting harms.

In order to interpret in the right way the prospective risks related to water jetting, it is initially essential to acquire a fundamental apprehension of the kind of work being done and the terminology applied. Water jetting or water blasting is a Water jet business procedure in which a stream of pressurized water is proposed at unwanted materials sticking to a substrate, such as the inside of a metal tank or paint on steel, concrete, or other material. The water stream is adjusted at the lower limit pressure to polish off the undesirable material though simultaneously keep off harm to the substrate material.

As with any kind of manufacture, the initial tread to be assumed before water blasting is to do a comprehensive Job Hazard Analysis (JHA). This tread is important for precluding workplace harms and should not become regular. The JHA sets the fundament of the project safety mindset and had better be conveyed with the support and engagement of impacted employees. The popular saying “two sets of eyes are better than one” is certainly suitable for setting the JHA. At the time it has been accomplished, it had better be illustrated carefully with each employee operating on the project before starting the process.

Safety risks associated with the water jetting or water blasting manufacture comprise noise, heat/cold harms, slips/trips/falls, bounded space entry, lockout/tagout, eye hurts, cuts, head hurts, and water blasting hurts. Though volumes can be written on each of these Water jet business issues, a concise illustration about each issue is referred to below.

Your Water jet business should remark that the environment in which the work is being done is oftentimes dirty and wet. Experience has indicated that a sufficient provision of disposable, moisture-resistant ear plugs should be preserved. This steps up with the regular altering of ear plugs by employees and brings down the probability for ear infections.

Environmental elements (Heat/Cold)

Industrial upkeep oftentimes introduces tough work environments, comprising cold and hot climate. Though water blasting in highly hot temperatures, you have the contributed Water jet business elements of moisture/humidity, personal protective gear, and sometimes radiant heat from the surrounding areas or gear. It is essential to stick to the fundamental rules of heat harm prevention through acclimatization, hydration, physical fitness, and rotation of employees at regular periods.